Intro

The sparkler filter press is utilized to remove solids from a fluid. This sort of machinery is made use of in food processing, pharmaceutical as well as chemical, beverage, cosmetic industry, etc. the price at which such sectors are growing in India is remarkable. With such a quick advancement price a consistent requirement for new and innovative technology is called for below. Although various equipments are utilized at various phases in the manufacturing facility, filter presses are called for at several of the last stages in creating a liquid. Industries require filter presses to make smooth the process if separating liquids. Prior to splitting up, the liquid - solid combination remains in the kind of slurry as well as requires to be cleansed before use. Filtering equipment is used to remove the solids from the liquid.

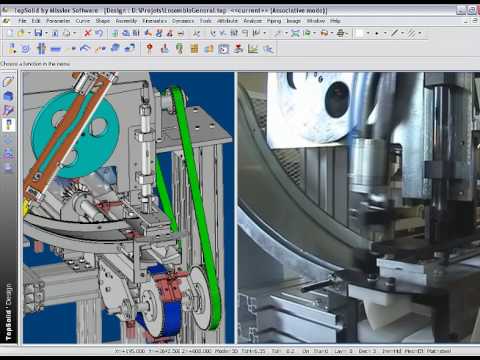

Construction

A large range of sparkler filter presses are available in the market right now. The vertical container has a number of horizontal filter plates in the filter cartridge assembly with perforated supporting displays, interlocking mugs and also filter media.

Procedure

The prime operation of the filter press is to filter the unclean liquid. With the aid of a pump, the liquid at high stress experiences the straight plates with raising stress. The filter plates hold back the impurities and also let the rest of the fluid to go through their facility by interlacing cups, which takes the filtrate to the outlet filter. A pump is made use of for increased stress by sectors where a reduced filtering time is important. Below home plates are utilized as filter media. A cake like framework of the solids filtered is based on the filter plates. The procedure of filtering system the fluid ends up being slow-moving when the fluid reaches its holding capacity in the cake.

Attributes

There are a great deal of advantages of utilizing the sparkler Filter Press. The machine available in the market comes hot press machine with a stainless-steel trolley so it can be walked around. The material made use of in its building and construction ensures that the machine does not corrosion, is durable and lasts a very long time. Some versions feature a moderate steel or stainless-steel jacket for filtering warm items. The filter press is available in a large range of sizes and diameters which can be modified according to the requirement of the customer. Two sorts of filter plates are readily available - deep as well as superficial. The variety of plates can also be differed as and when required. For constant procedure the filter press features a Back Wash center. The material utilized in the filter plates is strong and efficient in dealing with high pressure. It is immune to oil and water and also have outstanding air leaks in the structure which permits them to catch dust bits efficiently. These fiber filters are additionally resistant to high temperatures and can be used in factories where the items are warm.